Decarbonizing the products we use every day by turning waste CO₂ into valuable molecules, powered by renewables

The world has begun to electrify its energy systems but not its molecules. Every battery, wind turbine, and solar panel still hides a paradox: about 80% of the materials that build our modern life like plastics, perfumes, coatings, medicines, explosives, come from fossil hydrocarbons. And above 90% of those molecules are imported into Europe.

This dependency isn’t just unsustainable. It’s a strategic weakness.

At ReMoléculaire, sustainability isn’t just a goal, it’s our essence. Our mission is to craft cutting-edge, high-performance molecules that power the shift from fossil dependence to circular chemistry. By transforming carbon dioxide into new value, we’re reimagining the foundation of industry and shaping a world where progress and the planet thrive together.

Converting CO₂ into High-Value Chemicals and Materials

Electrochemical Alchemy

Our process uses electricity and waste CO₂ to make acetylene (C₂H₂), a compact, energy-dense molecule that serves as a clean building block for countless chemicals.

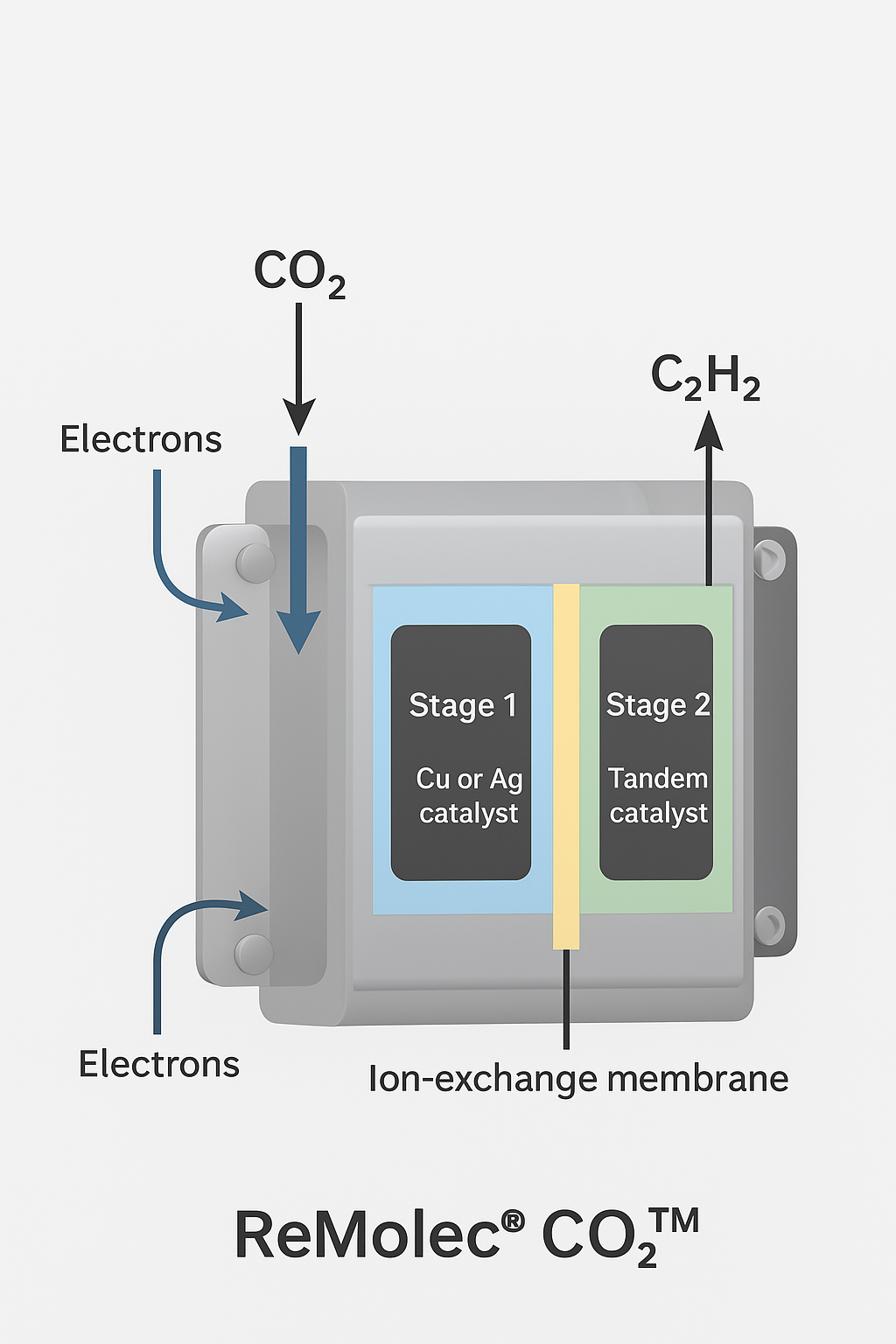

At the heart of the system is our electrochemical reactor, which uses renewable power to break down CO₂ and reassemble its carbon and oxygen atoms into new molecules. The process runs at ambient temperature and pressure, making it far safer and more efficient than traditional high-temperature fossil routes.

Each modular unit includes:

CO₂ preparation: The incoming CO₂ is cleaned and conditioned for the reaction.

Electrochemical cells: Inside, special catalysts and membranes drive the precise conversion of CO₂ into C₂ compounds like acetylene.

Product purification: The acetylene is then separated and refined to polymer-grade purity, ready for downstream use.

Energy recovery loop: Heat and gases are continuously recycled, minimizing waste and water use.

Because each reactor is containerized and modular, capacity can be expanded simply by adding more units. The result is a continuous, emission-free process that replaces fossil feedstocks with renewable carbon, redefining how the world produces its essential molecules.

-

Aromas & Essences

Crafting molecules that capture nature’s soul, engineered with industrial precision

Citral, the bright, lemon-like essence behind numerous fragrances and flavors, remains tied to fossil sources today. ReMoléculaire delivers a renewable breakthrough, producing citral directly from captured CO₂ powered entirely by clean electricity. -

BioPharma

Pharmaceutical chemistry demands uncompromising purity and traceability yet its core building blocks still come from fossil carbon and vulnerable supply chains. ReMoléculaire introduces acetylene as a clean, verifiable foundation for next-generation pharma precursors. Our next phase will deliver pilot quantities for validation into key intermediates like propargylamines and acetaldehyde derivatives.

-

Para-Xylene for Low-Carbon PET/PTA

Our high-selectivity para-xylene synthesis will redefine the building block for PET and PTA, the world’s most recycled polymer family.

By replacing fossil aromatics with CO₂, we will enable monomer-level decarbonization without changing existing infrastructure. -

Energetic Materials:

Toluene forms the cornerstone of defense-grade chemistry, serving as a critical precursor for TNT and a wide range of high-energy compounds.

We are on a mission to make fossil carbon obsolete.

We envision a world where every molecule, from perfume to polymer, originates from recycled CO₂. By uniting advanced electrochemistry with circular design, we aim to redefine the foundations of global chemical manufacturing and turn carbon from a liability into a limitless resource for a regenerative economy.

1. Molecule Sales

Direct supply of high-value, CO₂-derived molecules to sectors with urgent decarbonization needs (fragrances, defense materials, specialty polymers).

Drop-in compatibility with existing processes—no retooling—enables rapid fossil replacement.

Commercialization strategy

2. Platform Licensing

License our process for partners to run at their facilities with local integration.

Built for scale-oriented operators seeking clean-carbon capability and reduced dependence on fossil imports.

3. Molecule-as-a-Service

Containerized, point-of-use units operated by us; customers pay for delivered molecules.

Low-barrier, high-agility model for CO₂-rich, energy-aligned sites seeking climate performance without new infrastructure.